The LNER DC System

Background

Calls for electrification of all suburban lines out of Liverpool Street

originate in a 1905 Royal Commission and in a 1925 North & North East

London Traffic Enquiry, but only was authorised in 1935 when the Treasury

released loans for capital investment to attend to high unemployment after

the Wall Street Crash.1 First was a new “Shenfield Metro” service (as it came

to be known) on the four track section of the Great Eastern Mainline (GEML)

between Liverpool Street and Shenfield, although electrification of the rest

of suburban lines from the 1935

plans would not materialise for several decades.

Opening in September 1949, Liverpool Street to Shenfield is the oldest

stretch of mainline railway electrified with overhead line equipment (OLE)

in the country. The line from Manchester Oxford Road to Altrincham

(electrified by the MSJ&AR in 1931) would be older if it had not been

turned into a tram in the 1990s. There are other older OLE schemes as well

(Lancaster – Morecambe & Heysham, LBSCR ‘elevated electrics’, Newport –

Shildon) but all are now long gone. Along with the Manchester, Sheffield

& Wath scheme (otherwise known as the Woodhead Route), the “Shenfield

Metro” was planned and designed by LNER but finished under British Railways.

The two lines used very similar equipment, technical standards and EMU

rolling stock. Along with MSJ&AR line to Altrincham, these are the only

three schemes to have been implemented in the era when the British

government had chosen 1.5kV DC OLE as the national standard (1927 –

1955).

The scheme was also coordinated with an extension to London Underground’s

Central line from its then terminus at Liverpool Street to then take over

the Hainault and Woodford lines, removing them from mainline operations by

December 1947.2 This coordination included a cross-platform interchange with

the new Shenfield Metro service at Stratford. Other enabling works involved

junction remodelling and major re-signalling introducing multi-aspect colour

light working making that line one of the most modern at the time.

1949 Shenfield Metro

The first stretch of 1.5kV DC OLE to open on GEML was from Liverpool Street to Shenfield including the branch from Fenchurch Street over the Bow Curve connecting with the GEML at Bow Junction just west of Stratford. Along with sidings at Shenfield, Gidea Park and the main depot at Ilford, the scheme included all 4 tracks of the Up and Down “Mains” and “Electrics” throughout despite some earlier calls for the “Mains” to remain steam only from Gidea Park.3 As opposed to recent years, electric services terminating at Shenfield did regularly run on the “Mains” across a range of different stopping patterns regularly using double lead track connections between “Mains” and “Electrics” that are nowadays single lead and not in everyday use.

At Liverpool Street only platforms 11 to 18 were wired in 1949 as those platforms served the “Main” and “Electric” tracks of GEML and only a small proportion of trains out the station would be electric at this time.4 Similarly, only platforms 1 and 2 at Fenchurch street were wired with the “Fast” lines from 3 and 4 remaining unelectrified along their short length to Christian Street Junction.5 The route from Fenchurch Street to Stratford was wired for a theoretical shuttle service to run which never did. The whole rest of the route out of Fenchurch Street was wired later on of course, but the Bow Curve connecting it to GEML ever since its electrification to the present day has never been used for very much.

Steam Trains

As this scheme had to be compatible with steam traction in the area, the electrification needed to enable the watering of steam engines at some locations. Provision for watering by way of permanently earthed sections of OLE were located at the electrified platforms at Liverpool Street around the first electrification structure of each platform. Watering was also “confined to engine spurs” for some sidings outside Liverpool Street and for similar sidings at Gidea Park, Brentwood and Shenfield carriage sidings. At Shenfield platforms, Fenchurch Street and (later on) Chelmsford, the contact wire was set 20 ft above the rail. When the Southend line was electrified, watering was confined to the bay platform at Wickford, this would have been for trains on the Southminster line.6

Traction Power

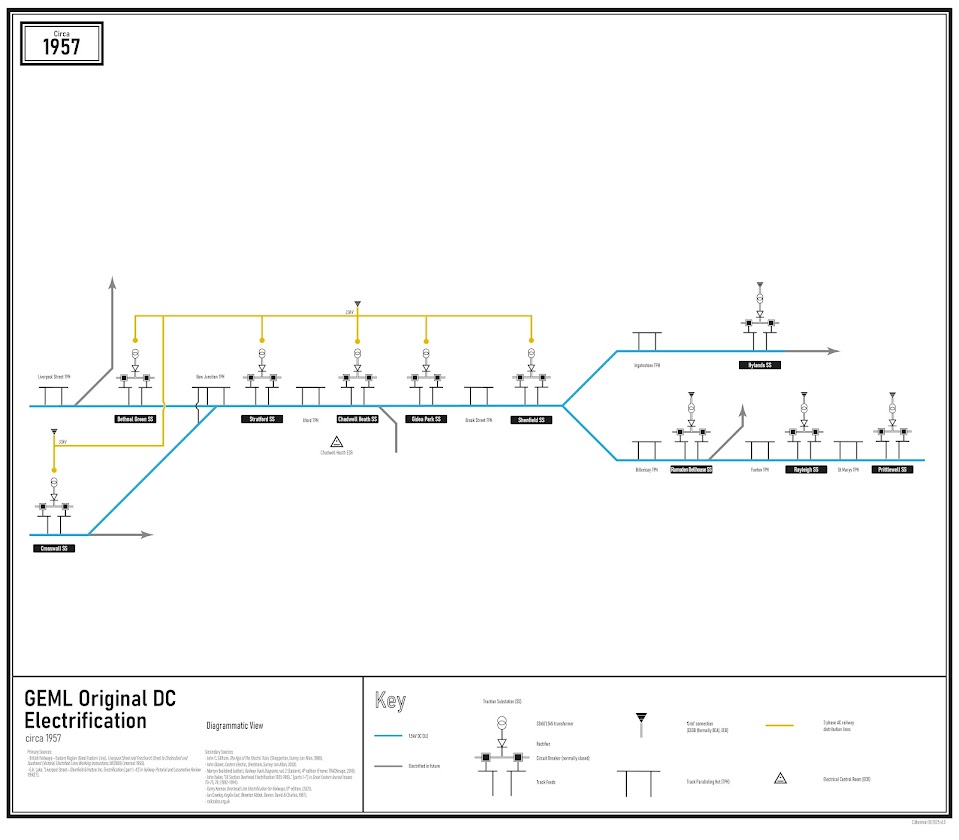

As with any low voltage system, the 1.5kV OLE needed regular supply points at rather short distances apart (compared to a higher voltage system). Electrification textbooks tend to say that the optimal distance between traction substations on a 1.5kV DC system is between every 2 and 8km.7 On this line, the traction substations were located at Bethnal Green, Stratford, Chadwell Heath, Gidea Park and Shenfield. There was also a substation at Crosswall close to Fenchurch Street station.8

All of the above substations were fed by 33kV 3 phase AC distribution cables owned and operated by the railway. I haven’t been able to find out much about these distribution cables at any great level of certainty. The 1956 working instructions mention that they are “routed on either or both sides of the line” and a couple of pictures from Railway Pictorial and Locomotive Review may suggest they were insulated and placed upon short posts just above ground level as I believe is similar to DC systems on London Underground at that time.9 The mention of both sides of the line may imply a dual circuit but I have heretofore not assumed that.

In any case, the 33kV distribution cables were supplied by the British Electricity Authority at the Chadwell Heath and Crosswall substations. Apparently at Crosswall the utility supply was relatively weak at 22kV and was stepped up to supply the distribution cables.10 Chadwell Heath is nearby to what would have been (or to become) Crowlands Grid substation that supplied the line in the 25kV era later on - so perhaps the BEA supply was from the start a lot stronger there.

Most DC OLE railways use additional traction feed wires running at OLE voltage and are electrically common to each OLE circuit. They are typically affixed to OLE structures above or around the catenary or laid underground on tramways. They regularly interconnect with the contact and catenary wires in order to reduce overall resistance and raise OLE voltages by providing extra conductors on the positive side of the circuit. As far as I can tell they were not used on the Shenfield Metro system.

Feeding Arrangements

Four Track Paralleling Huts (TPH) were constructed at Liverpool Street, Bow Junction, Ilford and Brook Street (sometimes referred to as Harold Wood).11 In the primary sources these are referred to as Traction Sectioning Cabins but these days that term is only applied to the equivalent substations on an AC system.

The TPHs generally occur between traction substations which is in keeping with the double-end feeding arrangement that is usually used on any DC railway. This refers to the system whereby each substation has dual supply equipment (rectifiers and transformers) that each supply one of two directions out from the substation. Each of those sections is also fed by one of the sides of the adjacent substations: hence "double-end". The OLE is fitted with an insulated overlap or section insulator that keeps the two sections electrically separate. However, a motorised bypass switch is connected to either side of the OLE that can be operated to unify the two sections if needed.

For instance, the section from Stratford to Chadwell Heath is supplied by half of both substations with the supplies reaching each other at Ilford TPH. At a track paralleling hut, the supplies are joined together at a DC busbar inside the TPH building but are electrically separated at the OLE (just like at the substation). When all equipment is working, the point of a TPH is to make parallel all the OLE circuits coming from either substation. On a four track railway like the GEML there would be at least 8 OLE circuits (at Ilford there would be more feeds for depot’s OLE) connecting through circuit breakers to the busbar. TPHs are also likely to occur at junctions where even more OLE circuits would be involved. Paralleling OLE circuits at a TPH reduces voltage drop and resistance as well as offering locations to quickly switch off traction power in emergency situations. It’s worth mentioning that there is no TPH between Chadwell Heath and Gidea Park. Perhaps the distance between the two was not enough to necessitate it.

It is not clear to me so far, whether bypass switches are installed on the DC busbar at a substation (supply or TPH), or if a substation has two busbars for each side and a bypass switch exists on the OLE overlap or section insulator. Educational diagrams seem to suggest that there is only one DC busbar and that the bypass switch is a separate component at the OLE level. If this is true wouldn’t this make the bypass switch redundant since the single busbar is unifying all the current from both sections?

The dual equipment at each substation adds resilience since if one rectifier, transformer or circuit breaker develops a fault, the substation can be run off one supply. Additionally, if a circuit breaker opens at one end of an OLE section, the substation still supplying will initiate Tee-feeding where the OLE bypass switch closed unifying the single-fed section with the normally fed one next to it. This long section is fed from two closed breakers in the middle at the Tee-feeding substation and one at the unneffected substation. 12 The TPH bypass switch can also be closed to enable a whole supply substation to be switched off.

AC Distribution Cables

The use of dual equipment at supply stations does somewhat imply the use of two separate AC distribution circuits, but as previously said there is no conclusive evidence either way that dual circuits were used on Shenfield metro. Due to this I have not drawn the distribution lines with dual circuits nor have I indicated the dual equipment that may have connected to each circuit at traction substations (for which there is no evidence either way).

Furthermore, it is not mentioned anywhere how the two BEA supplies interacted with each other. Perhaps the grid supply at Chadwell Heath normally fed the traction substations at Shenfield, Gidea Park and Chadwell Heath while Stratford, Bethnal Green and Crosswall took from the Crosswall connection. Then there would have been some kind of 33kV switching equipment available to unify the distribution supplies if one fell offline. Alternatively, the Chadwell Heath grid connection could have been doubled (since it was likely supplied from the 132kV Crowlands Grid substation), with one supply for the 3 substations towards Shenfield, and the other for the 3 substations heading towards London. In this case, the weaker Crosswall BEA supply would have been a single supply and backup only. Since none of that is certain, I can only draw the distribution cables in a simplified manner.

Chadwell Heath Electrical Control Room13

Due to G.H. Lake’s magazine Railway Pictorial and Locomotive Review, a surprising amount is known about the original control room at Chadwell Heath that administered the DC system from 1949 until the conversion to AC working in 1960. It used the Common Equipment system of Standard Telephones & Cables Ltd. who are said to have also supplied equivalent systems for the Watford DC line, Liverpool to Southport line and the Tyneside Electrics.14

At its core, the Common Equipment system uses a series of (presumably twisted pair) copper phone lines to communicate between control room and substation. Two phone lines constitute a single pilot. This is both for resilience should one break down but also to enable a second independent channel of communication up and down that pilot. At Chadwell Heath, 8 pilots were installed with four emanating in either direction. A single pilot can serve up to six substations therefore Chadwell Heath had the capacity to serve 36 substations before new cable would have to be laid. Although that may have been actually limited to no more than 18 substations on the western or eastern side of Chadwell Heath without alterations being needed to the spread of pilots. At its peak from 1956, Chadwell Heath would have controlled 6 substations westwards and 12 eastwards (total of 18) up from 6 west and 4 east on opening in 1949 (10 in total).

At the control room side there were two identical control desks each fitted with the Common Equipment and which would normally be manned by one of two operators. Between the two Common Equipment desks there was a set-up panel where switches were provided to connect any of the pilot networks to either the left hand or right hand control desk; this also had facility to connect to either the main pilot line or the backup within each pilot network. It’s not clarified whether selecting between which substation on any single pilot was done on the set-up panel or on the Common Equipment desks. There were also switches for viewing voltage and current meters for components within each substation and a switchboard for the electrification specific telephone network.

Other than the Common Equipment desks, there was a large mimic diagram on the far wall visible by both operators that permanently showed the status of all equipment in the system. Nothing is said of the AC distribution lines or the control of their supplies.

In short, the control desks contained generic controls applicable to any of the substations and whichever substation was desired at any moment could be connected to and controlled by either of the two desks. The benefit mentioned of this system over predecessors was that only one (or technically two) sets of control equipment was needed for multiple substations. Furthermore, the system was easily scalable with only a small amount of equipment needing to be added to the setup panel as more substations came online.

This is purely my own speculation but there is a potential problem with this arrangement in that it must require the Common Equipment desk to be sufficient for the most complex substation under the control room’s purview. On this initial DC system most substations were probably fairly uniform in design and the difference between equipment in a traction substation and track paralleling hut is not all that major. However the AC systems that were to come had much more bespoke and complex substation layouts which may have undermined the Common Equipment’s main advantage of not having to re-equip the control desk as substations are added. Furthermore this would lead to potentially confusing configurations of the control desk when it is connected to simpler substations as well as define a top level of complexity for all future substations in the system.

Dual control desks that can be switched to operate any component across the whole network set apart from a large mimic diagram that shows general status of all lines at a glance seems to have stayed the norm in ECRs ever since although with entirely different technologies. Usage of ECR pilots is mentioned in reference to control and monitoring systems used throughout the BR era until the emergence of IP based monitoring over the all-purpose railside fibre-optic network (“Fixed Telecoms Network”) that is being implemented at the moment.

Chelmsford and Southend Victoria

Seemingly, LNER planned in 1935 to extend to Chelmsford and Southend Victoria.15 These extensions were authorised in 1953 and planned to open before work began on LTS electrification, the logic being that a strong alternative route to London from Southend would be an advantage while LTS lines undertook regular disruption.16 Operationally, the services ran as extensions to the Shenfield Metro calling at some stations before Shenfield and a regular variation on the Southend line.17

Extension of the 1.5kV DC system to Chelmsford opened in June 1956 and the full line from Shenfield to Southend Victoria in December 1956. The work also included wiring Aldersbrook carriage sidings west of Ilford station. The extension used a bespoke type OLE design range (known as “SCS” for Shenfield-Chelmsford-Southend) based on but technically different to the “GE” style used on Liverpool Street to Shenfield (often called “GE/MSW” since the same design was used on the Woodhead route). Compared to GE design, SCS OLE design used galvanised steel instead of painted steel, a smaller cross-section of compound catenary, pin & cap insulators (unlikely to have been sufficient when 25kv was installed) and a through span wire for registration.18

In David Glover’s 2003 book Eastern Electric, the author mentions that an abnormally low OLE height was provided where the line passed by Southend Airport, writing:

Here [at Southend Airport], the overhead equipment was kept as low as practicable by locating the supports much closer together than normal. The structures were also painted with distinctive colours ‘for the additional safety of aircraft’. Sadly, it was not recorded whether this resulted in their being painted yellow, or maybe pink?19

When I reviewed the journal of the Great Eastern Railway Society, it was stated that the masts here were painted orange.20 This is curious because Glover explicitly mentions he referred to the Great Eastern Journal and the relevant articles predate the publishing of Eastern Electric by 9 years.

For traction power, 3 traction substations were constructed on the Southend line at Ramsden-Bellhouse, Rayleigh and Prittlewell, and one was added to the GEML named Hylands. Track Paralleling Huts were constructed at Billericay, Fanton and St Mary’s; and on the mainline at Ingatestone. Interestingly, the 33kV distribution cables were not extended to the new 4 new substations as they were each supplied directly by the Eastern Electricity Board at 33kV.21 It’s not said anywhere if Shenfield substation’s supply was upgraded to be able to power additional tracks to Ingatestone and Billericay, or if it was originally constructed to handle this.

The AC test system

Background

The 1955 Modernisation Plan had taken the decision to move from 1.5kV DC to 25kV AC at grid frequency for all future electrification (except for Southern region and Merseyrail). This system provides significant economic improvement especially for long-distance and high speed routes over low-voltage DC OLE. This is for several reasons:

- A higher voltage allows for a greater power draw by each train which is important for high speeds or heavier freight loads.

- In addition, less current is needed in the conductor with a higher voltage so the catenary can be thinner and lighter allowing OLE structures to need less material.

- For much the same reason that the power is transmitted more by the voltage than the current, high voltage transmission can travel much greater distances than low voltage power because there is less current involved that can encounter resistance or impedance.

- High voltage DC has the same advantage with distance but is mostly unsuitable because of the complexities of DC switching (especially historically speaking).22

- The longer transmission distances allow for OLE supply stations to be spaced out much further at around every 40 – 60km for 25kV AC compared to between every 2 – 8km for 1.5kV DC. Even further feeding distances can be achieved with 25kV AC by use of an Autotransformer (AT) system as will be seen much later on.

- This means that OLE supply stations (from now on “feeder stations”) can be connected directly to the public utility grid rather than the railway authority maintaining its own network of 3 phase high voltage AC distribution cables as is needed on DC systems.

- This significantly simplifies and cheapens the power and distribution (P&D) side of the electrification system and also allows a more reliable supply since the railway can rely on the whole nation’s electricity grid.

However, high voltage AC electrification was not initially plausible for railways due to certain technological advances in train equipment that took place postwar. It wasn’t until the early 1950s that on-board rectifiers and transformers became viable for use on rolling stock. This is why low voltage DC systems were often used in the earlier twentieth century since this could be connected directly to the traction motors. Traction motors supplied by AC were possible if the AC was at a low frequency, but AC traction technology that could run on utility frequency (50 or 60hz) wasn’t available until the 1970s.23 Low frequency AC systems were implemented in the UK on the Lancaster to Morecambe & Heysham line in 1908 (6.6kV 25hz) and on the LBSCR OLE system (6.6kV 25hz). In other parts of the world, this technology persists as a modern standard in Germany, Austria, Switzerland at 15kV 16.7hz; and in Sweden and Norway at 15kV 16⅔hz; and on some sections of the North East Corridor in America at 12kV 25hz. This system, although suitable for high power applications, requires the railway to own and operate a separate power grid at the reduced frequency and maintain complex converter systems to receive and convert power from the national utility. These systems often operate their own power stations as well.

When the 1955 Modernisation Plan chose 25kV AC 50hz, they also allowed for a lower voltage of 6.25kV to be used due to concerns for electrical clearances around low overbridges as this lower voltage was found to have similar clearances to pre-existing 1.5kV lines (importantly for the Anglia area). This required the use of dual AC voltage trains to be able to travel between the more urban parts of the network that had lower structures.

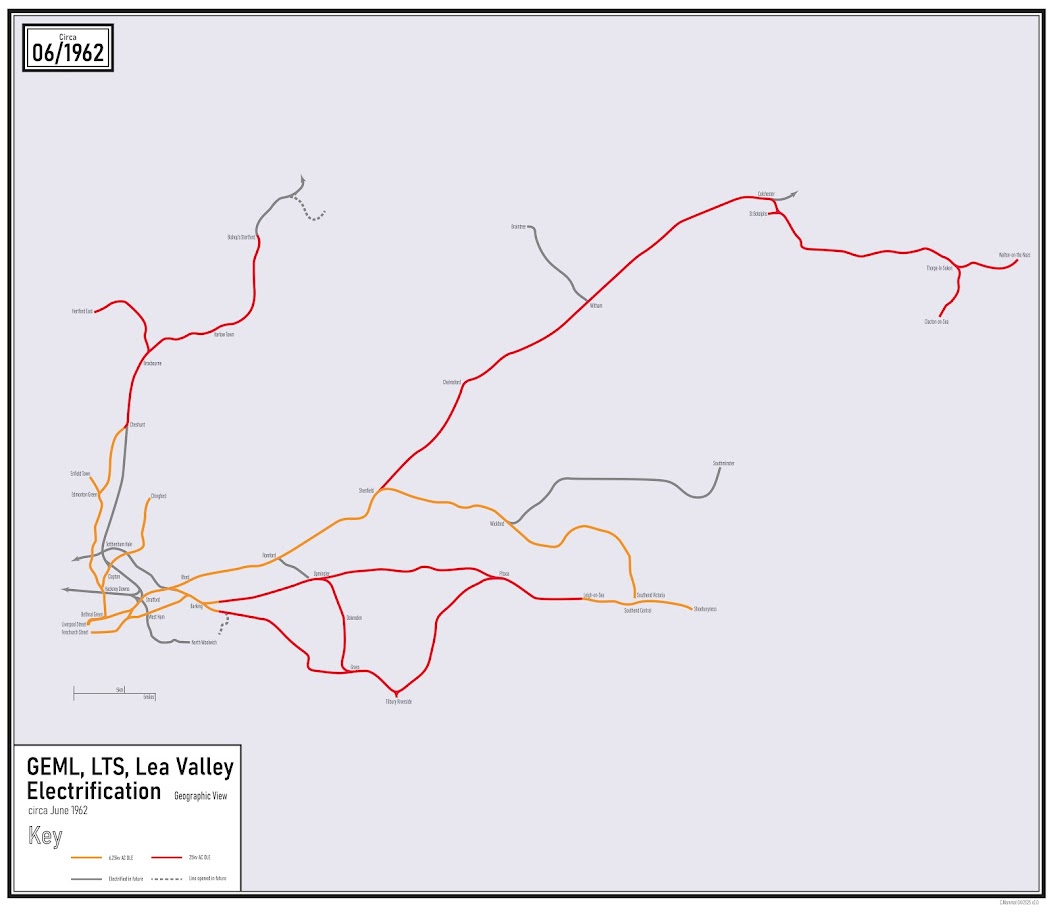

Two testbed schemes were installed to prove the 25kV technology, particularly the signalling immunisation and on-train equipment: the route from Colchester to Clacton and Walton (which would be used for dual voltage testing), and the Styal line in Manchester. Both lines were operationally isolated from the rest of the railway and ran a simple timetable making them good candidates for testing new equipment.

Colchester to Clacton/Walton

The full route between Colchester to Clacton-on-Sea as well as the branch from Thorpe-le-Soken to Walton-on-the-Naze as well as the short branch to Colchester Town station (at the time named St Botolph’s). At Colchester, only the one bay platform that served the route was electrified. Trials started from 1958 to early 1959 with the first revenue earning services beginning 16 March 1959 26.

Power was supplied by a 132/25kV feeder station at Colchester. The feeder station (FS) was destined to have two grid supplies for each direction as it was designed to also supply the line towards Colchester and Chelmsford for future installations. However, the second supply that would feed towards Chelmsford either wasn’t in use or wasn’t yet installed when the test system was commissioned. Nonetheless, an OHNS was installed at the FS just just out of Colchester station with the approach track to Colchester to be fed by the same supply that would feed down to Chelmsford. But initially, this neutral section was permanently through-connected until the extension of electrification a few years later meaning all lines were on the same supply. 27

The feeder station also housed an Electrical Control Room named “Colchester North” with remote control of all substations on the route. Rather than normal ECRs housing 1 or more Electrical Control Operators, Colchester North is always said to have had a “chargehand fitter” in control which probably implies the temporary nature of the control room until the system was joined up with that from London.28 I don’t think there is much difference between the two roles however.

Three Track Sectioning Cabins (TSC) were provided at Alresford, Thorpe-le-Soken (at the junction with the Walton branch) and at Clacton. The TSC at Alresford is of particular note as it was built with two OHNSs a short distance apart on the Down line only. This section (apparently around half a mile) was able to be switched to 6.25kV for testing the dual voltage equipment that was intended and fitted on all Anglia EMUs.29 This suggests that Alresford TSC was fitted with a 25/6.25kV transformer to step down the line voltage as was used later on the Chenford scheme. It’s stated also that this transformer and the neutral sections were usually bypassed and the line was fed normally when normal revenue service was taking place.30 The neutral sections at Alresford are mentioned in the working instructions of 1958 and 1960, but not in 1975 or any MoT report. Once full electrification to London was installed in 1962 it’s likely they would have been removed.

The other AC test scheme

The Styal line gets almost all the credit for being the first 25kV AC 50hz line in the country and while it ran the first ever train at 25kV, the Clacton line probably entered revenue service before the Styal line. It’s also well known that the Lancaster Morecambe & Heysham line was converted from 25hz to 50hz in November 1952 for trail running at mains frequency though still at 6.6kV.31 What’s less often mentioned is that, apparently, Fenchurch Street to Bow Junction was converted from 1.5kV DC to 6.6kV AC 50hz in around 1955/6 using LM&H units to test solid state Germanium rectifiers.32 This is further testament to how little used the Fenchurch Street and Bow Curve connection was.

The 1960 AC Conversion

The End of DC Power

Just barely 4 years after the extensions to Chelmsford and Southend, the full line from London was switched off to undergo conversion to a mixed voltage (6.25kV and 25kV) mains frequency AC system from 8pm on Friday 4th of November 1960 until 5am the next Monday when the full timetable was brought back into service under AC wires. 33 Some might say this was a poor utilisation of brand new equipment and many voices opposed the move stating that there was no problem with the DC system that needed to be fixed. For a mostly suburban system that it was, this is perfectly true.

However, had the DC OLE system been allowed to propagate throughout Anglia region, it would have become an especially expensive and annoying operational complexity that would have forgone the possibility of electric freight and compromised the development of electric suburban services on the North London Line which already have to deal with 750V DC third rail lines. Furthermore, it is a more efficient and cheaper to operate system especially at the scale of the whole Anglia region with two electric routes at over 100 miles in length. In my opinion, it’s a good thing they did the hard work of converting it when they did as it may never have happened if the DC network was let to carry on into the privatisation era. It’s also worth mentioning (as we will see) that as much of the original equipment that could have been re-used was recycled into the AC system.

Dual Voltage Trains

In my opinion, one of the most impressive feats of the conversion was the ability to modify the DC EMUs enough to become dual-voltage AC EMUs with the final conversion possible for all units at once across a weekend. On the 1949 stock, I believe the pantograph was moved to a different carriage where the AC equipment could be housed with the final connections to cut-in the AC machinery presumably fitted to be easily accessible for changeover weekend. Since the motors would have been 1.5kV DC, that was the voltage that the new transformer and rectifier would have output at.

The operation of the dual voltage mechanism depended on the action of the main air-blast circuit breaker and voltage sensing relays. Automatic Power Control (APC) magnets were fitted on the outsides of the tracks before and after neutral sections (whether they were voltage changeover points or not, as they still are at all neutral sections to this day). Detection equipment fitted to the bogies would activate the circuit breaker cutting all power to the train. Once the train had passed the neutral section, the second set of APC magnets are detected by the bogie mounted inducers which causes a lock to be released on the circuit breaker meaning its reclosing would be under the control of the voltage detection equipment. This consisted of 4 voltage relays that would allow for a line voltage between 4.1 and 6.9kV for the low voltage mode, and 16.5 to 27.5kV for the high voltage mode. If the first relay was tripped, the changeover switch was sent to the low voltage mode and the circuit breaker closed.

All four relays were activated if the voltage was above 16.5kV. In that case, the current was sent to a magnetic switch that would set the changeover switch at the transformer to the 25kV position. The other relays were installed to stop the changeover switch from being activated to low-voltage mode if the line voltage fell under 16.5kV but greater than 6.9kV. The changeover system was interlocked with the circuit breaker and the action of the APC magnets since any movement of the changeover switch while the circuit breaker was closed and connecting the system to any live current would cause destructive arcing for the internal components.34 At the transformer end, the changeover switch would control whether the transformer’s primary windings were connected in series or parallel, presumably for 25kV and 6.25kV respectively.35

Following testing and some in service incidents, modifications were made to the changeover equipment such that a switch to the low-voltage mode could only be made when the line voltage had dropped to below 3kV and then risen to 4.1kV, and that the re-closing of the circuit breaker is only made after a 2 second wait following the detection of the second APC magnet to ensure a correct reading of the voltage.36 All 92 of the original 1949 3-car sliding door units were converted at Stratford works for AC operation, as well as all 32 4-car slam door sets ordered by BR for the extension to Southend, both with new equipment provided by Associated Electrical Industries (Manchester).37 It’s believed that services to Chelmsford were more often operated by older sliding door stock.38 The LNER 1949 trains would come to be classified as class 306, and the original Southend DC trains as class 307.

Route Extents

The full route out of London London Liverpool to Southend Victoria was to be converted to 6.25kV. Clearly, insulators, clearance distances, substation layout and section lengths between feeder stations for 1.5kV was similar enough to 6.25kV that most of the same equipment could be carried over. Shenfield to Chelmsford was to be upgraded to 25kV. Since this involved many more alterations to the OLE and substations, the wires remained permanently earthed until re-energisation on the 20th March 1961 39 and electric service only resumed on 16 June 1962.40 Fenchurch Street to Bow Junction was also earthed until its re-entry to service (at 6.25kV) as part of the LTS scheme opening in 1961.41 Additional lines in the Stratford area were wired in 1960. In particular, carriage lines A and B between Bow Junction and Thornton Field at a yard that probably hasn’t existed for many decades now; and Stratford’s platforms 11 and 12 along with the associated “Up” and “Down Cambridge” lines (now known as “Up” and “Down Temple Mills”).42

Feeding Arrangements

As figure 3 shows, the AC conversion used almost all the same substations as the previous DC network, including the 33kV distribution cables. Neutral sections were installed at all feeder stations implying dual supplies were taken from the distribution cables. Once again, this may imply the distribution cables carried two circuits but also could mean that each supply took from a different phase combination in order to balance demand on the 3 phase supply. Presumably, a single phase 6.25kV traction supply was not enough to unduly disbalance a 3 phase 33kV DNO connection since the directly connected feeder stations on the Southend Victoria line were retained.

All the track paralleling huts were retained as track sectioning cabins (TSC) but only one (Brooke Street) was given a neutral section to become a midpoint track sectioning hut. Because of this, I suggest that most of the feeder stations had one side that was normally switched off and on hot-standby as a backup. There is no source for this, it is just my assumption.

The grid supplies for the railway distribution cables were altered however, with the weaker 22kV connection at Crosswall removed and replaced with a stronger 33kV one at Bethnal Green. This is mostly my assumption but It seems that the distribution cables may have been cut back from Shenfield, as Shenfield substation was substantially replaced by a new feeder station with a 132kV CEGB connection at a slightly different location to the old DC one.44

Shenfield needed to be more rebuilt so that it could supply 25kV to the mainline towards Chelmsford which it did once the OLE on that line had been suitably upgraded. This included replacing registration span-wires with cantilever arms and, of course, replacing all insulators. Additionally, Hylands TSS and Ingatestone TPH were removed completely.45 (Although a 25kV TSC was later installed in the Chelmsford area.)

Instead of continuing with the DC control equipment, a new electrical control room was built at Romford nearby to the original one at Chadwell Heath. The two control rooms would have briefly co-existed since the transfer of lines to AC took place in a staged approach over the changeover weekend.46 Unlike with Chadwell Heath, I could not find very much information on Romford ECR but it likely continued to use a system of pilot networks communicating with telephone line technology.

The 1960 "Chenford" Scheme

Route Extents

The North East London commuter lines had also been slated for electrification for as long as the Shenfield Metro service and these desires came true under the 1955 Modernisation Plan as a mixed voltage AC system. This was to be: Liverpool Street to Hackney Downs, Hackney Downs to Chingford, Hackney Downs to Edmonton Green (then known as Lower Edmonton), Edmonton Green to Enfield Town, Edmonton Green to Broxbourne to Hertford East (this section involved station reopenings), and Broxbourne to Bishops Stortford where the West Anglia Main Line continued unelectrified.

Importantly, the line between Clapton and Cheshunt via Tottenham Hale was not electrified at this time, the relative lack of suburban development (and large amount of industry) across that corridor probably being a deciding factor in this decision. The “Temple Mills” lines between Stratford and Tottenham Hale via Lea Bridge also remained unelectrified, as was the connecting route between Tottenham Hale and Seven Sisters via South Tottenham on the T&H line. Both would later be added in the 1980s.

Excluding anything north of Cheshunt, these lines are commonly referred to under the umbrella term “Lea Valley Lines”, which was a name given to the modern-day London Overground services in the area before they gained the title “Weaver Line”. However, this is potentially ambiguous since the route of the West Anglia Main Line specifically between Clapton and Cheshunt via Tottenham Hale was traditionally called the “Lea Valley Line” since it’s closest to the said river. Helpfully, this program of electrification used the term “Chenford”, a portmanteau for Chingford, Enfield, Bishops Stortford/Hertford.

The Shenfield Metro had electrified the platforms for the “Mains” and “Electrics” (11–18) so this scheme saw the rest of the station wired for the “Suburban” lines under Bishopsgate tunnel. Furthermore, carriage sidings at Chingford, Enfield and various loops around Bishops Stortford were electrified although most sidings remained without wires since they were entirely for goods and most no longer exist. The electrification opened to traffic on the 21st November 1960 on steam timings with the electric timetable beginning on 21 November 1960.47

Feeding Arrangements48

The majority of the Chenford scheme was at 6.25kV including the full lengths for journeys to Chingford and Enfield from Liverpool Street. The voltage changeover to 25kV was at the neutral sections south of Cheshunt station with all lines north of this point at the higher voltage. All OLE equipment was of the first standard BR design (mark 1) and electrical control from Romford as expected.49

On diverging from the GEML at Bethnal Green, the Bethnal Green FS also fed the WAML as well towards Stratford on the GEML and for the short but busy 6 track approach to Liverpool Street which was fitted with a TSC. Bethnal Green powered the North East Lines lines as far as Stoke Newington MPTSC on the Southbury Loop, and Clapton MPTSC on the Chingford Line.

The fact that a neutral section was added on the diverging WAML implies that Bethnal Green had three electrically separate supplies. However, the WAML neutral section was then removed in May of 1964,50 giving two sections: Liverpool Street through Bethnal Green to Stoke Newington/Clapton, and Bethnal Green to Stratford on the mainline. Because two of the previous three sections were united so soon after original installation, I have assumed that they were actually common from the start and the neutral section was only there for added N-1 flexibility which was later deemed unnecessary or it has something to do with the construction phase of the scheme.

As with everything concerning the 33kV distribution lines, there was no evidence available to me on how exactly they interacted with the railway feeder station at Bethnal Green which now would be requiring significantly more power in order to feed up to Stoke Newington and Clapton. Neither is there any indication on what the new (in 1960) grid connection there was like, only that it is “stronger”.51

Only one intermediate TSC was constructed at Hackney Downs where the lines diverge. After Clapton MPTSC, the rest of the Chingford line is supplied by a dual supply FS at Wood Street. Wood Street’s ‘Down’ supply took it to the terminus which had a TSC installed. Back on the Southbury loop, the next feeder station was at Silver Street — another double supply FS. Silver Street’s ‘Down’ supply fed the line to Enfield Town through Bury Street (Junction) TSC and Enfield Town TSC and on the Southbury Loop itself as far as Churchbury MPTSC.

After Churchbury MPTSC the rest of the route was supplied by the main 25kV feeder station at Rye House. Rye House’s ‘Up’ feed went as far as Cheshunt at 25kV. At Cheshunt TSC, a 25/6.25kV transformer was installed on the busbar and neutral sections in the OLE purely facilitate the voltage changeover.52 Therefore, Cheshunt TSC to Churchbury MPTSC was at 6.25kV fed by Rye House ‘Up’ supply. Presumably this arrangement was made so that additional 6.25kV capacity was available in emergency feeding arrangements without having to install an extra low voltage only feeder station.

The Hertford East line was also fed at 25kV by Rye House ‘Up’ supply with a TSC at Hertford East. The ‘down’ supply fed the rest of the route past a TSC at Harlow until Bishops Stortford where wiring ended. At Bishops Stortford there was an additional 25kV feeder station on hot standby to provide emergency feeding in case of an outage at Rye House. Although Rye House could support outages on the 6.25kV lines, the reverse is of course not possible so a second supply point was deemed necessary.

Bishops Stortford was the only single supply “tee-feeder” on the system although a neutral section was (at that time) installed at the end of wiring as this substation was expected to become a MPTSC if the electrification were to be extended to Cambridge.53 This did not in-fact transpire and Bishops Stortford was totally abandoned when electrification was continued down the line in the 1980s.

The 1961 LTS Scheme

Route Extents

This requires even less explanation since the whole of the London, Tilbury & Southend subnetwork was slated for electrification. Fenchurch Street to Bow Junction was electrified in 1949 at 1.5kV DC but this only included platforms 1 and 2, and the adjoining slow lines as far as Christian Street Junction. This section was used as a brief AC test bed at 6.6kV 50hz in 1956 and was left de-energised after the mainline was converted to 6.25kV AC in November 1960. This section along with all platforms and lines at Fenchurch Street was re-energised or wired on the 6th November 1961.54

At the same time as this, the rest of the LTS lines were electrified except for the Ockenden branch which entered service on the 18th June 1962.55 Because of the previous extents of the DC system, this electrification is often listed as Gas Factory Junction to Shoeburyness, plus Barking to Pitsea via Tilbury. The Tilbury Loop also included a small branch to Tilbury Riverside which was wired at the time although is now closed. Similarly to what happened at Stratford in the 1940s, Barking was rebuilt to accommodate London Underground’s District and Hammersmith & City lines with cross platform interchanges with the mainline platforms. Furthermore, a short section of the T&H (or Goblin) line was electrified at this point between Barking and Forest Gate Junction on the GEML.

Feeding Arrangements

Unlike on the Chenford lines, there were two (technically three) voltage changeover points on the LTS system. All routes were 6.25kV from Fenchurch Street until just after the divergence of the lines after Barking station. Each line had its own neutral section around Upney on the main route, and some way before Ripple lane yard on the Tilbury Loop. Both routes including the future Ockenden loop, the branch to Tilbury Riverside, and the reconvergence at Pitsea were at 25kV. A final changeover back to low voltage was at Leigh-on-Sea MPTSC. The Southend urban area was at 6.25kV all the way from Leigh-on-Sea to Shoeburyness.

From Fenchurch Street, the line was powered by a single-supply feeder station at Gas Factory until an MPTSC at West Ham and until a neutral section on the Bow Curve located near the bridge over the A12 - I don’t believe any substation has ever been fit at this neutral section. From West Ham to the two Barking neutral sections as well as up to a neutral section before Woodgrange Park junction was supplied by one side of Barking FS. Like on Bow Curve, the neutral section at Woodgrange Park was not fitted with a sectioning substation (at least at this time).

I have made some assumptions about Barking FS based on its implied layout in the 2010 images of Romford ECR. Therefore I have shown the 6.25kV section between here and West Ham as on the same supply as the 25kV from Barking to Upminster MPTSC, except with a 25/6.25kV transformer after the busbar. The other supply into Barking FS feeds the Tilbury Loop as far as Tilbury Town MPTSC. It is also possible that a third supply was taken at Barking to feed the low voltage lines but there is no contemporary evidence available to me so I can only draw on the anachronistic source.

When the Ockenden branch opened, it was powered by the Barking ‘Down’ 25kV supply as the MPTSC at Upminster was on the Down side of the junction. At the Tilbury end of the Ockenden branch, a neutral section (variably named "Chafford Hundred" or "Ockendon branch") separated it from the other Barking supply that was energising the Tilbury Loop as far as Tilbury Town MPTSC. The substation at Tilbury probably didn't adminster anything to the Ockendon branch since those two electrical sections also met each other inside Barking FS.

The next substation along was a dual supply 25kV FS at Pitsea. Since one neutral section was constructed before the convergence of the two lines, I infer that Upminster to Pitsea was on the ‘Up’ supply while Tilbury to Leigh (and backwards to Pitsea) was on the ‘Down’ supply. Since a substation was located at Leigh,56 I have made an assumption that a 25/6.25kV transformer was supplied at this MPTSC only to be used as a backup low voltage supply. I also make this assumption because it seems a neutral section was added further down the line at a new Chalkwell TSC in April 196357 which suggests that Leigh to Chalkwell was then supplied at 6.25kV by Pitsea’s ‘Down’ supply and via a transformer at Leigh substation (similar to the situation at Cheshunt and Churchbury which is suggested to have been a kind of standard practice).58 Furthermore, the 1962 Ministry of Transport report indicates a neutral section was at Chalkwell and that report was written apparently before the LTS project had actually finished.59 Because of this, it seems reasonable to assume a step-down transformer existed at Leigh-on-Sea MPTSC from the outset even if the feeding boundary was slightly altered by 1963.

In any case, the line from Leigh (later Chalkwell) was energised at 6.25kV by a single supply FS at Southend Central. A neutral section was fitted to this FS however the final section from there to the end of the line was powered by its own single supply FS at Shoeburyness. Therefore, I assume that only one grid supply powered Southend Central and that its connection to the last section of the line was backup only.

Standard TSCs were provided at Fenchurch Street and East Ham in the inner London area, at Dunton on the mainline between Upminster and Pitsea, at Purfleet between Barking and Tilbury, and at Golden Lane between Tilbury and Pitsea/Leigh.

Apparently, the whole LTS subnetwork had its own ECR at Pitsea. This is reported in the 1961 working instructions and the Ministry of Transport’s maps.60 But no mention of it is ever made again anywhere so I can only guess at what point its substations were transferred over to Romford. I have assumed that the neutral sections at Woodgrange Park Junction and on the Bow Curve were the control boundaries between the two ECRs.

Shenfield to Colchester

Remodeling

In closing the gap in electrification between Chelmsford and Colchester, Colchester station and junction was significantly remodelled to give a grade separated junction from the mainline onto the line to Clacton. Beforehand, Clacton was accessed by a double lead flat junction diverging on the Up side of the mainline. Now only one track diverged on the Up side, while another single track splits off on the Down side and dives under the mainline to join the Up Clacton line at Hunwick Junction. Predictably, what had been two neutral sections side by side on the double track line became one on either Clacton line as they ascended to meet Colchester station.

Feeding Arrangements

Upon conversion to AC, Shenfield to Chelmsford was de-energised for a year while conversion to 25kV took place with the new system being energised on the 20th March 1961.61 This was supplied by the new feeder station at Shenfield that had been, since November 1960, supplying two 6.25kV feeds to the mainline up to Brook Street MPTSC, and on the Southend line down to Billericay MPTSC. The 25kV continuation towards Chelmsford was probably energised by the same supply that fed low voltage to Billericay (via an extra 25/6.25kV transformer off the busbar) since that would have been quite a short section.

Like with Barking, I have made a few assumptions about the internal layout of Shenfield FS since it would have been handling two different voltages and capable of emergency feeding alterations. These assumptions are based on the 2010 images of the control room mimic panel. Since neutral sections were added on both lines after the junction, Shenfield would have been supplying three separate sections (6.25kV Brook Street MPTSC to Shenfield FS, 6.25kV Shenfield FS to Billericay MPTSC, 25kV Shenfield FS to Chelmsford).

I assume here that the Shenfield to Brook Street 6.25kV supply would have been able to cross the busbar to also supply towards Billericay in an outage. Similarly the 25kV supply for the section to Chelmsford could also supply towards Brook Street via the internal step down transformer for an outage on the other supply at Shenfield. However, the London side of Shenfield probably was unable to feed 25kV to Chelmsford if the country end supply was out of use.

I say this because, although Shenfield to Chelmsford was energised in 1961, passenger service did not begin until 16 June 1962 only a few days before electrification was opened as far as Colchester. I think this is because it was generally deemed important to have two separate sources of power (hence the backup 25kV FS at Bishops Stortford), potentially if Shenfield had two 25kV supplies in 1961, passenger service could have started earlier.

Alternatively it is also possible that two 25kV supplies were available at Shenfield but it was desired to have multiple sources of power that were geographically separate (like on the Chenford scheme). Or the delay in re-introducing electric service could be unrelated to feeding arrangements. Afterall, these concerns did not stop the original Colchester to Clacton/Walton scheme seemingly running off one supply, or at most, two supplies at the same FS.

In any case, full electrification between Shenfield and Colchester went into use on the 18th June 1962.61 The supplies from Colchester and Shenfield FSs were divided by an MPTSC at Witham. A TSC was fitted at Chelmsford and on the other side of Witham at Hill House.63 Hylands DC TSS and Ingatestone TPH were completely removed after only four years in use. The branch to Braintree remained unelectrified at this time.

Endnotes

LNER DC System

[1] Ian Cowley, Anglia East, (Newton Abbot: David & Charles plc, 1987), 9.

[2] John Glover, Eastern Electric, (Hersham, Surrey: Ian Allen, 2003), 37.

[3] G.H. Lake, “Liverpool Street—Shenfield & Hutton Jnc. Electrification part 1”, in Railway Pictorial and Locomotive Review 1950.

[4] Glover, 35.

[5] “Liverpool Street and Fenchurch Street to Chelmsford and Southend Victoria Electrified Lines: Working Instructions,” British Railway—Eastern Region (Great Eastern Line) (Internal 1956) BR29818: Appendix A.

[6] BR Working Instructions (1956), Appendix D

[7] David White, “AC DC Railway Electrification and Protection,” IET Railway Electrification Infrastructure Systems CONFERENCE (London), 2014, 28.

[8] BR Working Instructions (1956), Appendix A and B.

[9] BR Working Instructions (1956), 14 ; G.H. Lake, Part 1.

[10] John Baker, "GE Section Overhead Electrification 1935– 1969..." [parts 1–7] in Great Eastern Journal (1992) issues 71 page. 8.

[11] BR Working Instructions (1956), Appendix A and B.

[12] White, 31.

[13] All from: G.H. Lake, “Liverpool Street—Shenfield & Hutton Jnc. Electrification Part 3”, in Railway Pictorial and Locomotive Review 1950.

[14] The Tyneside Electrics network apparently gained a new control room in about 1949 or 1950 at Manors according to Glover, 15.

[15] Cowley, 10.

[16] Glover, 42.

[17] Glover, 45.

[18] Baker, GEJ, 72.26.

[19] Glover, 43.

[20] Baker, GEJ, 72.26.

[21] Baker, GEJ, 72.27.

Clacton/Walton test line

[22] I believe this is because of the fact that an AC wave crosses 0 volts so a circuit breaker can operate around that midpoint of the wave,

but of course this is not possible on DC. For what it’s worth, high voltage DC (HVDC) is technically more efficient than

high voltage AC and so is sometimes used by transmission grid authorities if a power line significantly exceeds 800km.

At that distance the losses caused by reactive power in AC lines is often more expensive than the complex switchgear and converter

equipment needed for HVDC. HVDC is also used in connections between independent grid networks and in underwater or subsea cabling.

[23] It should be clarified that modern AC fed trains do not directly connect the single phase OLE supply to traction motors either but

rather step it down to around 800V at the transformer, rectify it to DC and then supply the power to the motor control system which

inverts it to 3 phase AC at variable frequencies and voltages to optimally control 3 phase AC motors. It’s this variable motor drive

equipment that wasn’t proven until the 1970s.

[24] Glover, 69.

[25] Baker, GEJ, 73.25.

[26] “Colchester North to St. Botolphs, Clacton-on-Sea and Walton-on-the-Naze Electrified Lines:

Working Instructions,” BR Eastern Region (Great Eastern Line) (Internal 1958): appendix A.

[27] Final Report on the Accidents and Failures which Occurred in Multiple Unit Trains in the Scottish Region

and Eastern Region British Railways, Ministry of Transport/Railway Accidents, 1962, 8.

[28] Working Instructions, 1958, 6. The terminology “chargehand fitter” is used throughout this document.

[29] Working Instructions, 1958, 13 ; Baker, GEJ, 73.25.

[30] MoT 1962, 8.

[31] MoT 1962, 10.

[32] Baker, GEJ, 73.24

1960 AC Conversion

[33] Glover, 46.

[34] MoT 1962, 34-36.

[35] MoT 1962, 16.

[36] MoT 1962, 36.

[37] MoT 1962, 11.

[38] Glover, 44.

[39] Garry Keenor, Overhead Line Electrification for Railways, 6th edition (2021), Appendix A.

[40] Glover, 46

[41] Glover, 46

[42] Baker, GEJ, 74.18

[43] Baker, GEJ, 74.18

[44] Baker, GEJ, 74.19

[45] Baker, GEJ, 74.19

[46] Liverpool Street Traffic Manager, “Liverpool Street - Shenfield - Southend (Victoria)

Conversion from D.C. to A.C. overhead traction”, BR Eastern Region, (Internal: 18/10/1960), section XV.

Chenford

[47] MoT 1962, 8

[48] Mostly from:

“Second Interim Report on the Accidents and Failures which Occurred in Multiple Unit Trains in the

Scottish Region and Eastern Region British Railways”, Ministry of Transport/Railway Accidents, 30/05/1961, 5.

[49] Glover, 74

[50] According to http://www.railwaycodes.org.uk/electrification/neutral.shtm [accessed 09/02/2025]

[51] Baker, GEJ, 74.18

[52] MoT Second Interim Report, 1961, 5

[53] MoT Second Interim Report, 1961, 5

LTS

[54] Keenor, 2021, Appendix A.

[55] Keenor, 2021, Appendix A.

[56] Glover, 156.

[58] MoT 1962, 7. This document introduces the terminology of the “sub-feeder station” to describe a substation

that steps 25kV on one side down to 6.25kV. However, it only mentions this on maps and descriptions in reference

to the Glasgow area system. It does not mention the sub-feeder station fitted at Cheshunt MPTSC that we know

was in use by way of the Second Interim MoT report of 1961 (5), therefore I conclude that it may not have been

an exhaustive list of sub-feeder stations which is why I propose Leigh substation likely was one.

[An update on this matter 25/03/25] This cabride from after 1986 shows a substation at Leigh with a significant

[59] MoT 1962, map 2; and MoT 1962, 9.

[60] MoT 1962, map 2; “Working Instructions for Electrified Lines,” BR Eastern Region

(London Tilbury & Southend Line) (Internal 1961): 22.

Shenfield/Colchester

[61] Keenor, appendix A

[62] Glover, 78.

[63] MoT 1962, map 2.

List of figures

Figure 1: 1957 georgraphic: https://flic.kr/p/2qQ4W98

Figure 2: 1957 diagram: https://flic.kr/p/2qQaziE

Figure 3: 1960 geographic: https://flic.kr/p/2qQatmR

Figure 4: 1960 diagram: https://flic.kr/p/2qQbtgE

Figure 5: 1962 geographic: https://flic.kr/p/2qQbtB9

Figure 6: 1962 diagram: https://flic.kr/p/2qQ9rvv